Is It Hard to Change Rear End Gears UPDATED

Is It Hard to Change Rear End Gears

When it comes to the rearend of your car or truck, have you e'er thought well-nigh changing the gears? Of course you accept, you're a hot-rodder. Only like many, you probably have a few reservations almost starting the task. Don't be embarrassed, you're not alone. Hot rodders have been irresolute rearend gearing for years, scratch that, they have been paying someone to alter rearend gears. Merely why? Why pay someone else to do a job you can certainly do at dwelling?

Since many are reluctant to tackle this task, we thought we would try and help alleviate some of those fears by reaching out to Jeff Anderson at Moser Engineering, and take him requite some insight into this "black magic" of automotive upgrades.

It's not that the chore is physically tough to accomplish. Sure, it takes a few specialized tools, only they tin can ordinarily be purchased inexpensively. You might even have a friend that will loan them to you.

It's not that the chore is physically tough to accomplish. Sure, it takes a few specialized tools, only they tin can ordinarily be purchased inexpensively. You might even have a friend that will loan them to you.

The basic concern that many have, comes downwards to a lack of conviction. Installing a set of gears does require precision, and the math involved can be daunting. If not installed properly, a couple things tin happen: The gears will be noisy while driving the car, and/or wear prematurely and need replaced once again.

Setting your reservations aside, you'll larn that if yous accept your time, you as well tin swap rearend gears and realize swell results. To help alleviate the concerns that many people have virtually installing rearend gears, we decided to put together this footling outline to demystify anything that might seem like a black magic of sorts. This is not an install article, only rather, just a guide to help you decide if taking on this task is something for you.

We started by request Jeff, what was the one piece of communication he could requite someone before they start tearing their auto's rearend apart if they are thinking about treatment a gear swap themselves.

"I would say have someone help you lot who has washed it earlier… At least as an over the shoulder teacher or guide. Some parts of the process are more than can be discerned off YouTube videos, and being your first time, yous want to make sure you are following the proper steps. You really need to understand the interaction of the pinion to the band gear, the preload, shims, and everything else that is critical to setting upwards a ring-and-pinion," he said.

Okay, maybe that didn't instill much confidence in y'all, but it really is skillful advice. If you've never worked on your car'southward rearend, it is a setting-sensitive slice of the automotive puzzle. Just and then again, so is rebuilding just about whatsoever aspect of a machine, and y'all learned near of the other puzzle pieces, then, yous got this. It as well relays the fact that this is something that does require patience, a solid knowledge of how a rearend works, and finally, the proper tools.

What's What?

Like we said, this is not going to be an installation article, just rather, an informative piece that gives you some insight into some of the terminology and conditions that will need to be understood. For instance, backlash is not something you see when you incorrectly answer your wife's question, "Exercise these jeans brand my…" Trust me, automotive backfire is a good thing – the other ane, not so much.

Backfire

This describes the clearance betwixt the ring gear and the pinion gear, and is usually measured in thousandths-of-an-inch by using a punch indicator. For instance, US Gear recommends .008- to .012-inch for street employ and .006- to .008-inch for competition use. Backlash between the ring-and-pinion gear is set after the pinion gear is properly installed. Backfire is adjusted by calculation shims to either side of the differential side (carrier) bearings. The side bearing preload is also adjusted when setting the backfire. There is no specific number to achieve when preloading the carrier bearings per se, merely when you lot accept backlash set, the differential should non spin freely enough that it coasts when you spin it then permit become. As well, you do not want information technology too tight. Compare information technology to loading or slightly tightening a front bike bearing.

Backlash is the crucial setting of the ring gear contact of the pinion gear. If in that location is too much backlash, the ring gear needs to motion closer to the pinion gear. If there is non plenty, the ring gear needs to motion away from the pinion gear.

Just like the side bearings, the pinion bearings are adjusted past adding and removing shims of varying thickness. Afterward the pinion bearing preloads have been set, this is the time that backfire is set. You will exist checking the gear mesh pattern with dye or marking compound. Shoe shine is non recommended – especially for the novice, as information technology does not brand the wear design as visible.

What happens if backlash is as well tight or besides loose: Too tight will generate excessive heat and chop-chop vesture out the gear. If it is too loose, this will allow the gears to beat on each other, and yous will eventually fracture or break teeth off the gears. Either mode, the rearend will be noisy.

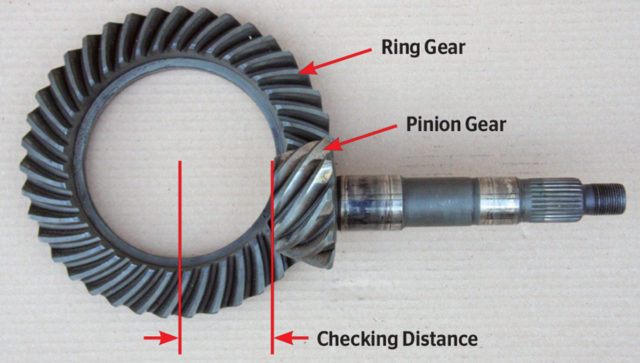

Pinion depth is the distance from the axle center line to the end face of the pinion gear (checking distance).

Pinion Depth

Since we mentioned the pinion gear in the previous paragraphs, we should give a piddling explanation about that piece of the puzzle. The pinion gear is the input gear of the rearend to which the driveshaft connects. This gear delivers the power from the engine to the ring gear, which and then send it to the wheels. This gear requires a specific depth be achieved within the rearend housing when installed, and is fix with the use of shims. The shims control how the pinion contacts the ring gear in relation to the axle center. Pinion depth is fabricated deeper or shallower past calculation or removing these shims.

When it comes to setting pinion depth, Jeff had this to say, "Having the right tools volition save you time and eliminate headaches. I would suggest renting 1 from a local parts store if that is an selection. Information technology is cheap, and volition save y'all a ton of headaches and worry about getting it right." None of our local motorcar parts stores carried the proper tool, only nosotros establish a elementary pinion depth-setting tool from Ratech that is bachelor through Elevation Racing and it but cost $25.00. While this is non what many would call a "precision" tool, information technology is a relatively cheap pick for the hobbyist, and information technology will go y'all very close.

Crush Sleeve

The beat sleeve is basically a soft bushing or spacer that is used to concur the inner and outer pinion bearings apart and offering some resistance when tightening the pinion nut. When installed, the pinion nut is torqued to spec, compressing the "crush sleeve" until proper pinion begetting-preload is accomplished. I thing to go along in heed when working with a beat sleeve, is that it is a one time utilise detail. If you over tighten the pinion when setting the bearing preload, you will have to replace the sleeve – information technology's not reusable.

While the crush sleeve (left is the factory method for filling the space between the pinion bearing and setting begetting preload, a solid spacer is an alternative.

We also asked Jeff if there were any tricks or an like shooting fish in a barrel way to deal with a crush sleeve.

"At that place are not really whatever tricks when it comes to setting upward a gear. Shortcuts are not brash. 1 thing to remember when you get to higher horsepower applications, yous may need to use solid shims instead of a crush sleeve, as high horsepower power can cause the crush sleeve to compress nether extreme loads, which could change bearing preload," he said.

Having the right tools will save you lot time and eliminate headaches. – Jeff Anderson

The solid shims (or spacer) that Jeff mentioned is not collapsible like a crush sleeve, and a spacer can be reused if need be. For instance, if you lot have a leaking pinion seal and demand to replace it, if using a vanquish sleeve, yous will also need to replace the sleeve. If using a solid spacer, it is reusable.

Drive/Declension

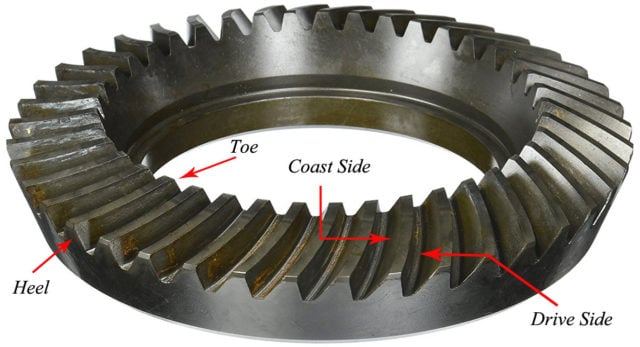

When someone mentions the drive or declension area of the gear, this refers to the "face" of the ring gear's teeth. The drive side of the tooth on the ring gear is what contacts the pinion gear when the vehicle is accelerating. When someone mentions the declension side of the gear, this is the backside of the tooth on the ring gear that is contacted past the pinion gear when the vehicle is decelerating. When setting upwardly gears, the set up specifications will mention this.

Wear Pattern

This is a visual interpretation of gear mesh that lets you know if you have the gears ready correctly. A "blueprint" refers to the visible molar-contact area on the ring gear that is exposed when using a gear up upwards dye to come across how the ring gear and the pinion gear mesh. This is where the confront and coast side of a gear tooth comes into effect.

Proper vesture pattern is adamant by the pinion depth. A proper wear blueprint shows the wear centered on the gear teeth.

Preload

The pinion bearings and the differential's carrier bearings must run a little "snug", and have a sure amount of resistance (preload) they need to overcome. This is similar to the way a wheel bearing should be loaded during assembly. The bearings require this "snugness", in lodge to eliminate any play within the bearing. This "preloading" is measured by checking the torque, usually with a "axle style" torque wrench that is required to turn the bearings.

The Gear

When it comes to the describing the ring gear, in that location is the toe of the gear, which is the portion of the tooth surface that is nearest the heart of the ring gear. The heel of the tooth is the area nearest the outer border of the gear. The height country of a gear tooth is the surface at the very the acme of each tooth.

Time For A Alter

Every gear has a required set of measurable parameters that need to be established during installation. These must be followed then that the gears don't make dissonance when driving, and so they last as long equally possible. When you are rebuilding and need to make pinion gear-depth changes, it is general practice to use shims measuring inside the range of .002-inch to .004-inch at a time, until the correct wear pattern is achieved.

When a change in backlash is required, shims approximately 1 1⁄ii times the amount of change required are typically needed to bring the gears into spec. For case, if y'all need to change the backlash by .004-inch, shim(south) measuring .006-inch is a starting point. The bodily corporeality of change obtained will vary depending upon the gear ratio and gear size.

A loose or high backlash (too much), is corrected by shimming the differential and moving it closer to the pinion gear. A low or tight backlash (not enough), is corrected by moving the differential away from the pinion. Correcting these atmospheric condition is hands done by moving shims from one side of the differential to the other.

This pinion-depth tool is relatively inexpensive, and is a good option for the home enthusiast equally opposed to the otherwise expansive precision tool.

That Doesn't Sound Correct

Sometimes, your rearend will brand an unwanted noise. Okay, nosotros'll wait for you to stop giggling… Anyhow, in regards to your car, this can happen before or immediately after a rebuild. If the rearend in your car is making an unwanted audio, understanding what causes it should be the beginning step in diagnosis.

Humming Noise

If you hear a humming sound coming from the rear of your ride, that is not typically acquired by anyting going bad, but rather, an incorrectly installed ring-and pinion-gear. Typically, the dissonance is created when at that place is too much backlash. Incorrect installation of the ring-and-pinion gear prevents proper molar contact and can cause rapid tooth habiliment and gear failure. This humming noise converts into growling noise when the wearable increases. A humming noise tin can also be due to worn out bearings, which need to be replaced.

Noise When Accelerating/Decelerating

A dissonance that gets louder while your vehicle is accelerating, probably ways that there is heavy contact of the pinion-gear teeth on the outer ends of the band-gear teeth (pinion gear not set deep enough). Conversely, if the noise gets louder when the vehicle is coasting or decelerating, it probably ways in that location is non plenty molar contact (too much backlash).

"Sometimes it can be hard to distinguish betwixt differential noise, pinion or carrier bearing noise, axle begetting noise, and gear noise. A ring-and-pinion can have racket related to the bearings that hold the alignment to one another. As the bearings wear out, the gear engagement, alignment or depth tin can modify and cause these bug. Sometimes it can be a pinion bearing causing the noise considering of a bad driveshaft bending or load. Of course, sometimes the gears just habiliment out," Jeff informed us.

Knocking Dissonance

A knocking or clicking audio may exist due to the splines on the axle shafts beingness worn out, in which case the defective shaft has to be replaced. Another cause could be the result of a chipped tooth on one or more of the gears in the differential. If that is the case, they'll need to be replaced.

Noise When Turning

If at that place is a noise coming from the vehicle'south rearend while making a plow, this audio is usually due to trouble in the beam shaft, or a problem within the differential itself. More often than not, a bad axle bearing is the reason for the noise that occurs when cornering. When the noise comes from the correct side of the machine during a right turn, it normally means that the outside beam begetting is worn. If that is the case, if yous turn in the opposite management information technology will ordinarily reduce or even eliminate the racket if information technology is a bad axle bearing.

installing the shims to arrange pinion depth does require a store press, every bit the begetting is a press fit to the pinion shaft. Setting pinion depth ordinarily means removing and reinstalling the begetting multiple times to become the proper depth.

If the cause of the racket is coming from deep within the rearend at the differential, this can be caused by either tight-meshing gears, or likewise much backlash on these gears. Another cause could be that the differential-case bearings accept gave up the ghost. These tin can besides cause noise when turning.

While nosotros will concede that swapping the rearend gears of your automobile is non something to exist taken lightly, hopefully, this overview about rearend gear set up is enough to give you lot the encouragement you need to tackle this job yourself.

DOWNLOAD HERE

Is It Hard to Change Rear End Gears UPDATED

Posted by: shelliehicall.blogspot.com

Comments

Post a Comment